The global demand for high-quality animal feed continues to surge, driven by the expanding livestock sector, rising meat consumption, and a growing emphasis on animal welfare and nutrition. For feed manufacturers, the key to staying competitive lies in optimizing every stage of the animal feed production line—from raw material handling to final packaging. This guide delves into the essentials of designing a high-performance animal feed manufacturing system, addressing challenges like energy efficiency, feed safety, and sustainability while incorporating actionable strategies for modern feed mills.

1. Core Components of a Modern Animal Feed Production Line

A well-structured animal feed production line integrates multiple stages, each playing a critical role in ensuring consistent, nutritious, and cost-effective feed. Let’s explore the key components and how to optimize them:

a. Raw Material Handling & Precision Storage

The foundation of any feed production line begins with efficient grain cleaning and sorting machines, which remove contaminants like dust, stones, and foreign particles to prevent equipment damage and ensure feed purity. Bulk storage silos equipped with automated moisture control systems protect grains from spoilage, while real-time inventory tracking minimizes waste by preventing overstocking.

For small-scale operations, compact feed ingredient storage solutions offer space-saving benefits without compromising on accessibility. Meanwhile, large industrial plants benefit from pneumatic conveying systems that streamline raw material transfer between silos and processing units.

b. Grinding & Particle Size Optimization

Achieving the right particle size is crucial for animal digestibility and feed efficiency. Energy-efficient hammer mills with adjustable screens allow manufacturers to fine-tune grinding output for different feed types, from coarse mash for ruminants to fine powder for poultry.

For high-capacity operations, roller mills provide a more consistent grind with lower energy consumption, making them ideal for large-scale cattle feed production. Pairing these with dynamic particle size analyzers ensures every batch meets nutritional specifications, reducing the risk of under- or over-processing.

c. Advanced Mixing for Nutritional Consistency

Uniform ingredient distribution is non-negotiable in feed manufacturing. Horizontal ribbon mixers excel at blending dry ingredients, while vertical ploughshare mixers handle both dry and liquid additions—such as fats, enzymes, or molasses—without clumping.

To address the rising demand for customized animal feed formulations, some manufacturers are adopting AI-powered mixing controllers that adjust ingredient ratios in real time based on sensor feedback, ensuring every pellet delivers precise nutrition.

d. Pelleting & Extrusion for Enhanced Feed Quality

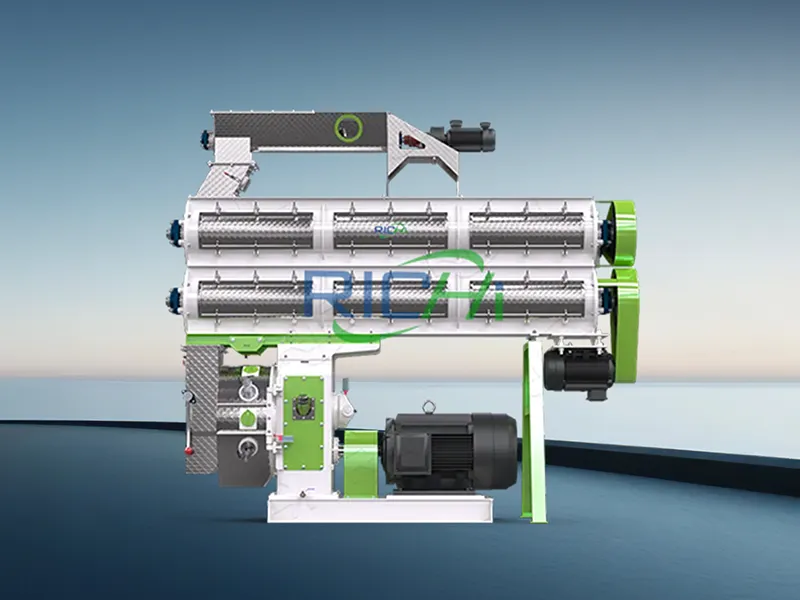

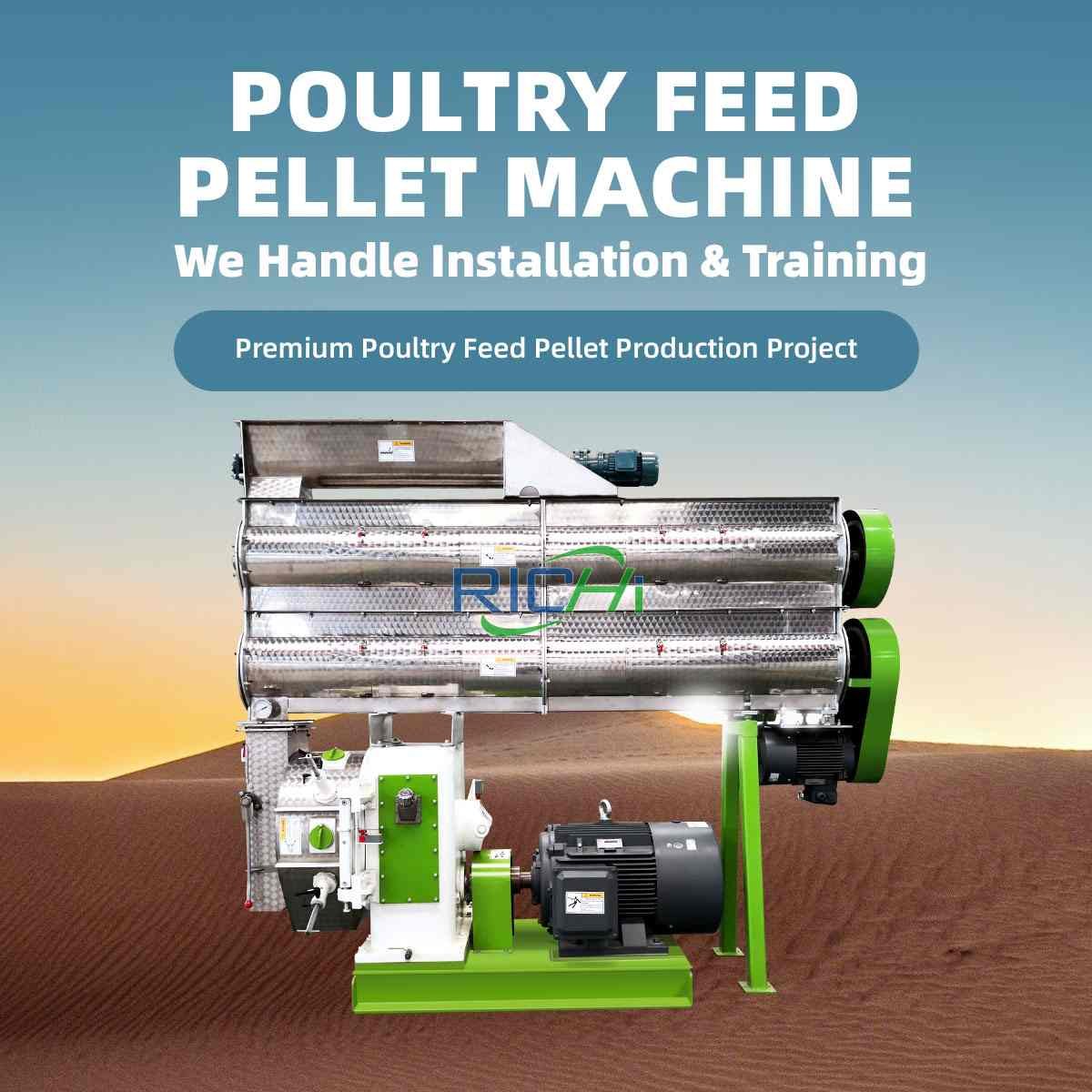

Pelletizing transforms powdered feed into durable, dust-free pellets, improving storage stability and reducing feed waste. High-capacity animal feed pellet making machines with variable die speeds allow manufacturers to produce pellets of varying sizes and densities, catering to species like pigs, poultry, or fish.

For specialized feeds, twin-screw extruders create textured products with improved palatability—a must for aquafeed production or premium pet food lines. Pairing extruders with post-extrusion drying systems ensures pellets maintain their shape and nutritional value during storage.

e. Post-Processing Cooling & Drying

Freshly pressed pellets retain heat and moisture, making them prone to mold growth if not cooled promptly. Counter-flow pellet coolers efficiently reduce temperatures while minimizing moisture loss, preserving nutrient integrity. In humid climates, low-temperature feed dryers prevent caking without degrading heat-sensitive ingredients like vitamins or probiotics.

f. Automated Packaging & Distribution

The final step—automated bagging machines—seals feed into durable, tamper-proof bags, with options for bulk bag filling for large-scale farmers. To meet eco-conscious consumer demands, some manufacturers are switching to biodegradable feed packaging made from plant-based materials, reducing plastic waste.

(Important Site: https://pelletisingmachine.com/animal-feed-machine/)

2. Overcoming Key Challenges in Feed Production

a. Managing Raw Material Price Volatility

Fluctuating grain prices strain profit margins. Local sourcing partnerships and multi-feedstock flexibility—such as using alternative proteins like insect meal or distillers’ grains—help stabilize costs without compromising nutrition.

b. Reducing Energy Consumption

Feed mills are energy-intensive operations. Waste heat recovery systems capture excess heat from pellet mills to pre-warm incoming ingredients, while solar-powered feed production lines slash electricity costs in sunny regions.

c. Ensuring Feed Safety & Compliance

Contaminated feed risks animal health and brand reputation. Metal detectors and X-ray inspection systems at critical points in the production line intercept physical hazards, while HACCP-certified sanitation protocols prevent microbial contamination.

d. Embracing Sustainability

From carbon-neutral feed additives to closed-loop water systems in aquafeed plants, sustainability is no longer optional. Zero-waste feed manufacturing initiatives, such as repurposing processing byproducts into bioenergy, are gaining traction among forward-thinking producers.

3. The Future of Animal Feed Production

- Precision Livestock Farming (PLF): Smart sensors in feed bins monitor consumption patterns, enabling data-driven feed optimization to minimize waste and maximize growth rates.

- 3D-Printed Feed Customization: Emerging technologies allow for on-demand 3D-printed feed pellets tailored to individual animals’ dietary needs, though widespread adoption remains years away.

- Circular Economy Models: Collaborations between feed mills, breweries, and food processors are turning organic waste into high-protein feed ingredients, reducing reliance on traditional crops.

Conclusion

A modern animal feed production line must balance efficiency, quality, and sustainability to thrive in today’s competitive market. By investing in automated feed processing equipment, adopting energy-saving technologies, and prioritizing nutritionally optimized formulations, manufacturers can meet evolving demands while reducing operational costs.

Ready to transform your feed production line? Our experts specialize in designing turnkey animal feed manufacturing solutions that boost productivity by up to 30%—from small-scale poultry feed plants to large industrial complexes.